Compliance with DoD's Radio-Frequency Identification (RFID) requirements is two-fold. RFID labeling itself is pretty straightforward, as RFID-capable thermal-transfer printer availability is wide, as is the availability of pre-encoded RFID tags for lower-volume shipping needs. Of course, there are some challenges, due to the physics of radio wave interaction with containers and other materials, but in most situations the technology works without a hitch.

For most, the biggest challenge is data management:

•Collecting RFID Case (exterior container) tags, and correlating those with

oCLIN quantity

oUID containers

•Aggregating Case tags onto Pallets

•Supplying RFID and correlated UID data to Wide Area Workflow (WAWF)

There are three ways to get RFID data into WAWF:

•Manual data-entry into WAWF web site

•Transmit RFID and UID (container) data as an EDI Pack Update

•Include RFID and UID (container) data in an EDI Receiving Report (DD250), transmitted to WAWF

Option One is fine for companies with low shipping volumes. Option Two involves creating a Receiving Report in WAWF, and marking the RFID section as Pack Later.

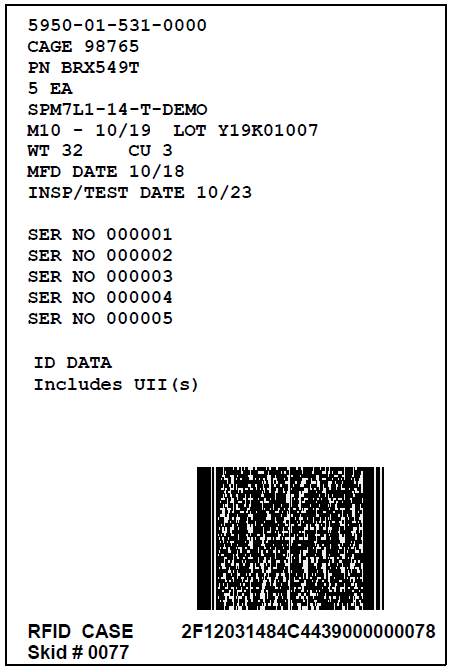

Then an EDI Pack Update is transmitted to WAWF by a DoD-certified Value-Added Network (VAN), which fills in the RFID data in the shipment as though it was entered with the Receiving Report. This can happen in parallel with acceptance of the shipment by the Govt's QAR. MIL-Comply supports the Pack Update in two ways:

•Pre-encoded RFID tag data is entered into MIL-Comply RFID Manager, which makes it easy, even with moderate numbers of UIDs.

•Labeling collects CLIN and UID data as it prints RFID container labels, collates it as it prints RFID Pallet labels (if applicable)

The RFID Manager allows review and manipulation of the RFID data, if necessary, and prints a Load Configuration report to allow for internal quality assurance. Then, with a couple of clicks the data is on its way to WAWF.

When shipping UID items, that data has to be entered twice. Once for the CLIN each is shipped against, and again in relationship to the RFID container that includes it. At some point it makes sense to use MIL-Comply's WAWF Automation which allows the user to enter UIDs once, and provides several ways to simplify that. Labeling automatically assigns RFID tags while it aggregates UIDs and automatically palletizes. Then Shipper sends an EDI Receiving Report (DD250), including the UID data to WAWF. The DD250 can include the RFID and UID container data, or it may be sent later as a Pack Update if that works better for your process.